Injection mold making is what brought us where we are now. Up to the present time, we focus on customer satisfaction as our number one priority. Now that we have established our name in injection tool making, we expand our expertise to various industries.

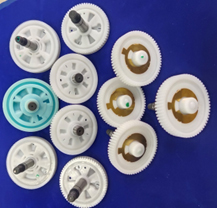

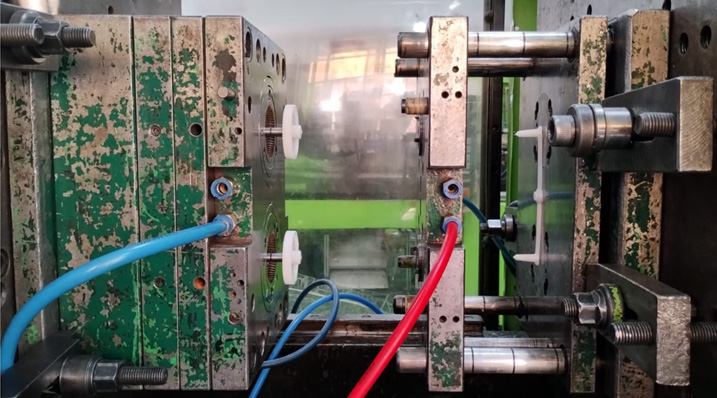

Plastic injection molding with tools we build in-house is our specialty. Coupled with around 65 injection machines ranging from 35Tons to 480T are capable of running large productions.

Suba is recognized by major OEMs in many industries for our reputation as a highly-experienced and pioneering custom injection molder. We utilize the latest in manufacturing and automation technologies in our 80,000 square foot, purpose-built molding facility to give you high quality parts at the best possible price.

Our Manufacturing has widespread molding industry experience and applies the best practices of lean manufacturing ideologies throughout our operation. A highly trained technical staff operates our plant 24/7.

We have solutions for your all sort of Injection moulding machines such as Horizontal, vertical, Horizontal cum vertical, 2K shot, Over moulding are done with one of the Finest manufacturing machine makers such as Engel, Fanuc, Wittman Batten field, Milacron, TKC, JSW,etc.

All of our machines are equipped with hopper driers and other auxiliary equipment’s like mould temperature controllers, Hot Runner Systems etc. The plastic manufacturing factory is backed up with captive power generators ensuring that Customer requirements are fulfilled.

The classic manufacturing process for thermoplastic products. By designing the injection tools based on the specific product requirements and by defining the correct production processes we are able to offer high precision components on a competitive cost level.

Combining two materials in one mould, for example PP and TPE, is an efficient way to provide high volume components. 2K moulding processes save handling, improve alignment, and offer better quality in finished goods.

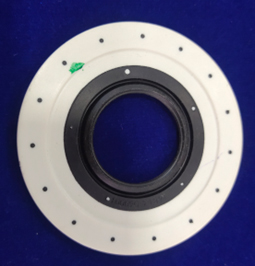

Components are precisely inserted in the mould before the injection process and will therefore be integrated in the final part with an optimal connection.

With this process we encapsulate a component like a metal, brass, SS a sensor or similar with plastics and by that are able to protect it against media contact.

As we take care of our health in clean way, we of course take care of our products demanding a cleanliness.

The classic manufacturing process for thermoplastic products. By designing the injection tools based on the specific product requirements and by defining the correct production processes we are able to offer high precision components on a competitive cost level.

Whether your parts requires tight tolerances, have complex geometry or are highly cosmetic, our technical staff is battle tested and can meet your difficult molding requirements. If your parts require post-molding operations or full contract manufacturing, we offer a complete range of in-house assembly, testing, and packaging services.

Raw materials we deal with,

With an experience of 4 decades, we have almost processed all kind of Thermo-polymers with our wide variety of Products needs and applications

Please send us your inquiry, our team will get in touch with you

* Mandatory fields